A Biased View of Premier Aluminum Llc

A Biased View of Premier Aluminum Llc

Blog Article

Everything about Premier Aluminum Llc

Table of ContentsSome Known Factual Statements About Premier Aluminum Llc The Single Strategy To Use For Premier Aluminum LlcThe Premier Aluminum Llc DiariesSee This Report on Premier Aluminum Llc

(https://share.evernote.com/note/c347bf0b-f141-6fd8-d335-2be93ad98d74)Generally, a buyer's primary duty was to locate competent and receptive providers. In some situations, purchasers thought that any type of distributor ready to contractually satisfy the acquisition demand was certified. However, using low cost and unqualified providers can create top quality problems, and lost time and money in the future. To aid you via the procedure, here are some points to take into consideration when picking the right metal casting vendor.

A firm that just uses the financial investment spreading procedure will attempt to offer you on why that process is best for your application (Foundry near me). What if using the sand spreading procedure is best for you and your requirements? Instead, look for a distributor that provides a series of casting procedures so the very best option for YOU is picked

If collaborating with a solitary source for all of your casting requires is very important to you, the provider needs to be varied in its abilities. When incorporated with various other integrated abilities, this can aid streamline and press the supply base. When selecting the ideal casting vendor, mindful consideration should be offered to top quality, service, and price.

The Premier Aluminum Llc Statements

Buyers progressively select casting suppliers that have machining capabilities. This can avoid conflict if defects are uncovered throughout machining. If a 3rd party is machining, it might lead to "finger-pointing" regarding that is at fault. Is it a casting problem or a machining problem? If the spreading vendor discovers an issue during machining, the problem is solved faster with no disagreement over whose mistake it is.

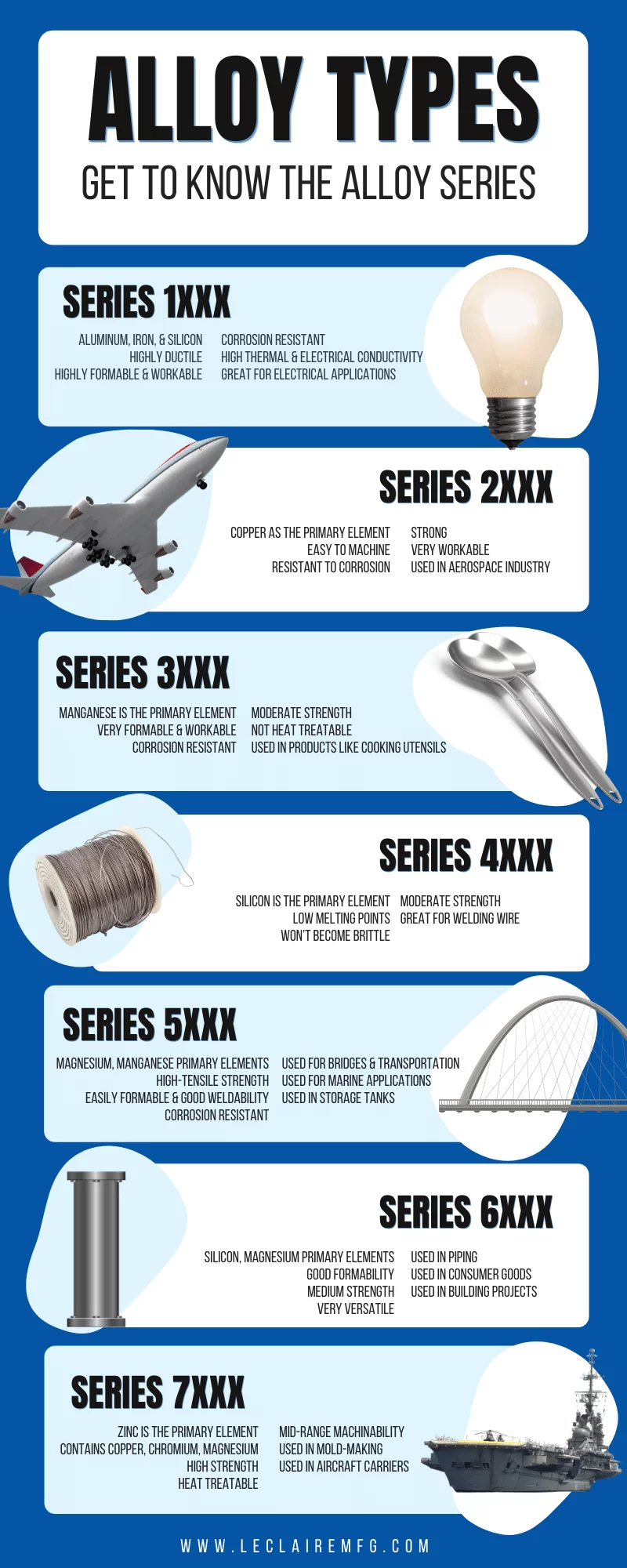

Trouble or no, integrated machining simplifies the supply chain and lowers taking care of time and shipping expense before the item makes it to the customer. What do you require from your spreading supplier? Are you seeking somebody to simply deliver a metal component to your doorstep or do you need more? If you do not have in-house metallurgy know-how, validate that the supplier can offer support in choosing the appropriate alloy based on your specific application.

Others will certainly surpass the letter of the PO to help you save money and time. Do you have needs for both ferrous and non-ferrous alloys? Some foundries are restricted or specialized. Make sure the supplier can satisfy all your material or alloy demands to get rid of the requirement for several providers.

6 Simple Techniques For Premier Aluminum Llc

Research study the vendor's website. Speak to a sales associate or service associate. Ask a great deal of concerns. Visit their facility. Get an understanding of what they can do for you and if you can see yourself constructing a strong, shared connection with them.

Light weight aluminum is likewise light-weight and has great rust resistance, making it perfect for applications where weight and longevity are essential factors. Furthermore, aluminum casting is a cost-effective technique of production, as it needs less energy and resources than various other approaches. Iron casting, on the various other hand, involves pouring liquified iron right into a mold to produce a desired form.

Little Known Questions About Premier Aluminum Llc.

Iron spreading is also able to withstand high temperature levels, making it suitable for usage in applications such as engine parts and industrial machinery. Nevertheless, iron spreading can be a lot more pricey than aluminum spreading as a result of the greater cost of raw materials and the power required to thaw the iron. When determining in between light weight aluminum casting and iron spreading, it is essential to consider the particular requirements of the application.

In final thought, both aluminum spreading and iron casting have their very own unique benefits and drawbacks. There are 3 sub-processes that drop under the group of die spreading: gravity die casting (or irreversible mold casting), low-pressure die casting and high-pressure die casting. To obtain to the completed item, there are 3 main alloys used as die spreading material to pick from: zinc, aluminum and magnesium. Report this page